Project Description

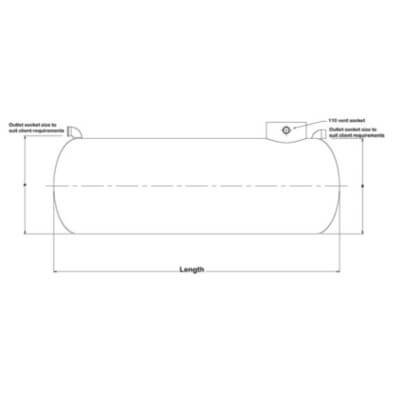

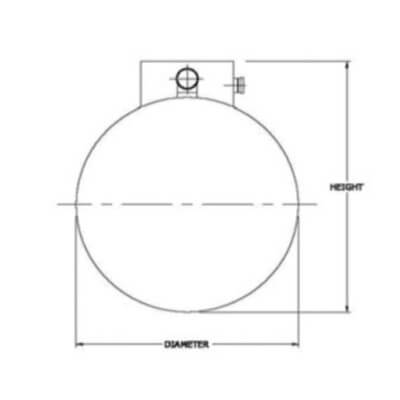

Full Retention

These units treat 100% of the flow. They are used where there is a foreseeable risk of oil/hydrocarbon pollution, such as vehicle maintenance areas, fuel dispensing points, and oil depots.

The range of Full Retention Separators from an NS4 through to NS100

The Class 1 Full Retention Separators have silt storage capacity, a coalescing filter, and Automatic Closure Device. This prevents any stored pollutants being discharged from the separator.

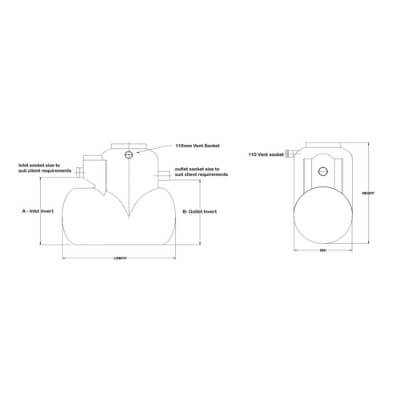

Bypass

These units are used in hard standing areas where there is a light risk of hydrocarbon contamination to the surface water run-off, i.e. Car Parks, Roadways, Industrial Estates, Goods Yards etc.

These units are designed to treat the influent up to the design nominal size of the Separator.

Excess flows over and above this are allowed to ‘bypass’ the oil retention chamber, ensuring the stored pollutants remain within the separator. Ranging from the NSB3 to the NSB 100.

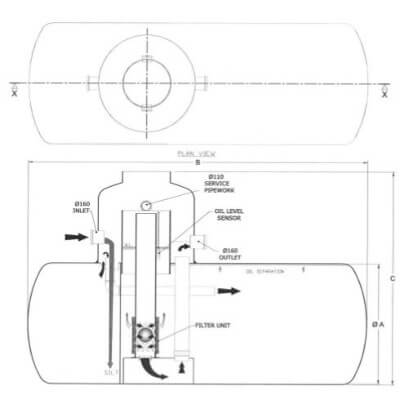

Forecourt

These are similar in design to the Full Retention separators, only with a minimum volume of 10,000 litres.

This is to provide sufficient storage capacity to contain the entire contents of a road delivery tanker compartment (7600 litres).

The separators offered have been independently tested and are fully compliant with Environment Agency PPG3 guidelines.